Professional Series

Tower Farms

Professional

Tower Farms Professional manufactured by Tower Garden.

The Professional Series of Tower Farms is designed to be used in larger, more commercial oriented spaces, such as farms or greenhouses. However, it is also the ideal solution to create breathtaking indoor farms in shopping malls, business centers, corporate headquarters, schools, universities, airports, or even in homes with large spaces!

A Tower Farm system is delivered as a full-turnkey 100% automated solution! The Professional Series towers are modular in size and are designed to grow up to 52 plants per tower. These are the only aeroponic systems which can be used indoors or outdoors (patented technology in the USA).

The Professional Series is perfect for professional growers, charities, community gardens, startup businesses, restaurants, hotels, schools, cafeterias, convention centers, building atriums & lobbies, airports (like in Chicago O’Hare), large families, etc.

Tower Farms also thrive on rooftops and are designed to sustain strong winds in heavy stormy climate conditions!

In partnership with our partners at Agrotonomy, Beyond Organic can help you plan your Tower Farm and/or design your greenhouse regardless of the scope and size of your project!

Frequently Asked Questions

A: About the Technology

A1: What is "Tower Farms"?

Tower Farms are a cutting-edge patented American agricultural technology that merges two methods of farming; Vertical Farming and “Aeroponics”.

Vertical Farming is when crops are stacked on top of each other instead of being laid in a horizontal fashion, and “Aeroponics” is a soilless method of farming where the roots of the plants are actually hanging in the air 24/7.

Our Tower Farm technology is made by Tower Farms / Tower Garden USA, the originators of the technology.

A2. What is the difference between Hydroponic & Aeroponic growing?

Technically, aeroponics is a branch of hydroponics. Although unique, Aeroponic farming relies on water and soluble nutrients as well like conventional hydroponics.

However, in conventional hydroponics, the roots of the plants grow in a substrate and are immersed at all times in a constant flow of water enhanced with insufflated oxygen + soluble fertilizers.

With Aeroponics, the roots of the plants just hang in the air and are fed intermittently. Due to the fact that the roots have 100% oxygen availability 24/7, the delivery of nutrients to the plant is unparalleled.

Aeroponics uses less water than hydroponics. In a hydroponic system, plants are grown in a water-based nutrient solution, which requires a large amount of water. However, in an aeroponic system, plants are fed intermittently (on average 10 minutes per hour) with a nutrient-rich solution, which uses up to 50% less water than hydroponics. This makes aeroponics a more sustainable and eco-friendly option.

Aeroponics also promotes faster plant growth and higher yields. In a hydroponic system, plants’ roots are submerged in water and are susceptible to oxygen deprivation, which can slow down growth. In contrast, aeroponics allows plant roots to receive higher levels of oxygen, which facilitates faster growth and yields.

Aeroponics even provide a more sterile growing environment than hydroponics. In hydroponics, pathogens, and diseases can easily spread through the water, which can result in plant loss. In aeroponics, the nutrient solution is not a conducive environment for pathogens to thrive, which means that plants are less likely to be affected by diseases. This is what happens when the roots are just hanging in the air with 100% oxygen availability.

While both aeroponics and hydroponics offer a soilless farming alternative, aeroponics is a better option due to its numerous benefits, including water efficiency, faster plant growth, and higher yields, a more sterile growing environment, and the ability to grow a wider range of crops.

Scientific comparative tests have proven that crops grown on Tower Garden aeroponic systems feature a superior nutrient density and show an increase in antioxidant and phenolic values. Furthermore, Aeroponics delivers on average 35% increase in crop yield and 40% water savings in comparison to conventional hydroponics. Please visit this study if you haven’t already!

Beyond Organic provides towers made by the originators of the technology, Tower Garden. Tower Garden has been manufacturing hundreds of thousands of Aeroponic towers for over one decade. Tower Garden technology was the first Aeroponic tower on the market (back then named Future Growing), so Tower Garden is the pioneer of Aeroponic tower technology and commercial Tower Farm systems.

A3. Why “Beyond Organic”?

The inspiration behind our name, Beyond Organic, was from a research conducted on the resulting crops of Tower Farms, where they were compared to traditionally grown Organic crops.

It was irrefutably proven throughout this extensive scientific comparative research, Tower Garden® Aeroponic commercial systems produce 35% to 50% crop yield increase in comparison to soil-based farming and conventional hydroponics.

A4. What are the Towers made from?

Tower Farms are made from the safest high-end UV-stabilized, BPA-free, food-grade PC/ABS proprietary plastic formula.

The high-quality resins used by Tower Garden are compliant with both U.S. Food and Drug Administration guidelines for food contact and European guidelines for Restriction of Hazardous Substances. Our resin material is also completely opaque — Keeping light out, inhibiting algae growth, which is a common issue with cheap knock-offs.

The PC/ABS which has been engineered for the manufacturing of Tower Garden has been successfully tested for chemical leaching all the way to the nano particle, unlike the cheap towers sold by no-name shops.

Although technically our proprietary PC/ABS is considered to be plastic, Tower Garden is the only soilless-food growing-system which has been approved for LEED projects (LEED: Leadership in Energy and Environmental Design). In fact, Tower Garden has been approved for LEED projects due to the durability of the material used to build the towers, in conjunction with the low energy and high crop yield of our technology.

When it comes to traditional agriculture, whether organic or nonorganic, nutrients are stored in plastic containers; Hoses used for irrigation systems are petroleum derived; Tractors are fuel powered; Crops are stored in plastic containers after harvests, etc. Furthermore, traditional organic agriculture uses tons of plastic mulch made from wasteful plastic material (which quality is far inferior to the material used to make our towers).

Our PC/ABS proprietary formula is the safest plastic ever engineered for agricultural-related equipment.

Some Tower Farms have been using the same towers for the last 10 years. The longevity of a Tower Garden is unparalleled in the hydroponics- aeroponics industry. No one in our industry uses a PC/ABS material as safe, as thick, and as durable whether used indoors or outdoors.

So, in other terms, when it comes to quality, our Towers are the absolute best in the business.

A5. How much water does a commercial Aeroponic tower use?

On average, a traditionally planted crop consumes 1.5L of water per day, while in Tower Farms it is around 0.116L per day.

A6. What is the fertilizer used?

We use a Tower Garden® proprietary nutrient ionic mineral solution by the name of ‘Tower Tonic®’.

Tower Tonic® is the most unique all-natural mineral-based nutrient solution ever formulated. In fact, contrary to conventional hydroponic farming where a different nutrient mixture is needed for each crop, Tower Tonic® can be used for all vegetables, herbs, fruits and flowers which can be grown on Tower Garden® towers.

It is 100% natural with zero chemicals, made from the purest earth minerals that are required for the healthiest plant growth possible.

Whether minerals are created through natural organic mineralization (decaying process of animal and plant waste in soil to get the non-organic minerals), or obtained from mining the earth, as long as they are free from man-made harmful chemicals, it is exactly the same for the plants, there is no difference.

Ammoniacal Nitrogen vs. Nitrate Nitrogen

Ammoniacal Nitrogen is used in commercial farming to create an ‘explosive growth effect’. Although it does a great job in terms of forcing nature to grow bigger and faster, it weakens the cell structure of the plants. This makes them more prone to pests & diseases while producing an inferior crop in terms of nutrient values and flavor qualities. This is why instead of using ammoniacal nitrogen, we use nitrate nitrogen which is the purest and most effective way to produce a healthy crop featuring high nutritional qualities.

Derived from: Potassium Nitrate, Potassium Sulfate, Magnesium Sulfate, Boric Acid, Copper Sulfate, Manganese Sulfate, Sodium Molybdate, Zinc Sulfate, Phosphoric Acid, Calcium Nitrate, and Iron Sodium EDTA.

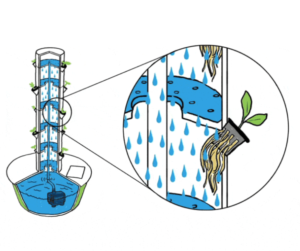

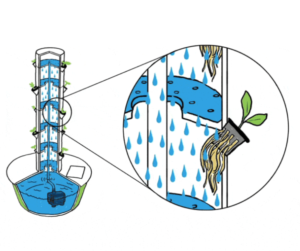

A7. How does a Tower Farm automated irrigation system work?

The tower has water channels built-in. A submersible pump at the bottom of the reservoir pumps water (which is mixed with the minerals) through the water channels to the very top of the tower, and then via the use of specially positioned drilled holes, water falls onto the roots of the plants much like a shower, irrigating them.

Once the cycle ends, all excess water goes back down to the reservoir to be used in the next irrigation cycle.

In the Professional Series, our irrigation systems have been designed to supply the water and fertilizers to each tower on an as-needed basis regardless of the number of towers involved.

A tower growing strawberries will require more water and nutrients than a tower growing parsley.

A Tower Farm irrigation system entails the following:

– Container for nutrients A

– Container for nutrients B

– Gravity tank (size varies according to the amount of towers).

– Dosatron nutrition automatic dozing system (2 or 3 units depending on Tower Farm set up and the quality of the water).

– Manifolds (size varies according to Tower Farm configuration)

– Floaters for each tower

– Valves for each tower

– Modification of each tower (holes drilling to accommodate floaters and valves).

– Tubing to supply water and nutrients (size of tubing depends on the size of the Tower Farm and its configuration).

We also like to keep a water tank inside the greenhouse as the irrigation source, so that the water is room-temperature at all times.

Example of an irrigation system set up at Beyond Organic’s Pilot Tower Farm in Kuwait:

A8. What is the ideal temperature for a Tower Farm featured inside a greenhouse?

The ideal temperature inside a greenhouse is 22°C to 25°C. However, this is just a “ideal guideline”. In fact, crops such as hot peppers, okra etc. can sustain a much higher ambient temperature than crops such as spinach, lettuce...

It is recommended to have a differential temperature with cooler temperatures at night than the daytime.

In Beyond Organic’s Pilot Tower Farm in Kuwait, in spite of the scorching desert heat which can easily cross the 50°C mark in the summer, the state-of-the-art greenhouse runs without air conditioning at an average of 24°C during the day.

B: About the Tower Farms

B1. What are the specs of the Professional Series aeroponic towers used in a Tower Farm offered by Beyond Organic?

Professional Series Towers (also knowns as Commercial Grade Towers) are modular in size and can be configured as follows:

Regular-Towers for Regular Crops:

28 plants per tower • 1.8 m (height) • 7 stackable modular sections.

36 plants per tower • 2.1 m (height) • 9 stackable modular sections.

44 plants per tower • 2.5 m (height) • 11 stackable modular sections.

52 plants per tower • 2.9 m (height) • 13 stackable modular sections.

Micro-Towers for Baby Greens:

100 plants per tower • 1.8 m (height) • 13 stackable modular sections.

132 plants per tower • 2.1 m (height) • 17 stackable modular sections.

164 plants per tower • 2.5 m (height) • 21 stackable modular sections.

196 plants per tower • 2.9 m (height) • 25 stackable modular sections.

– The bottom reservoir has a 50L when in use. It also features a floater device as part of the irrigation system and a drain valve.

– Regular planting pots feature 4 planting areas per pot.

– Micro planting pots feature 8 planting areas per pot.

– Each tower is equipped with a small submersible pump.

B2. What exactly are the Micro Towers?

The Micro Towers by Tower Garden were originally designed to grow micro greens (of course!) but is widely used to grow “petite vegetables” and wheatgrass.

Considering that every crop that has been ever tested scientifically growing on a Tower Farm shows an increase in nutrient density, people using wheatgrass therapeutically should truly consider wheatgrass grown on a Micro Tower for its superior nutrient values and increase in antioxidant properties.

Also, our Micro Towers should be renamed “Strawberry Towers”! In fact, recent tests rank these towers as the only viable Aeroponic tower solution to grow strawberries commercially. If you’re thinking about growing strawberries, these are the towers to do so!

Whether using rock wool or coco coir, there is no need for a planting basket nor a clip to plant the seedlings, thus facilitating the process and reducing labor.

The maximum height is our Micro Tower featuring 25 Pots (196 planting ports) – 2.9 m high

Within a CEA environment, in a climate-controlled greenhouse, we advise using the maximum size/height: 25 Pots (196 planting ports) – 2.9 m high to optimize space.

Anyway, whether they are called “Micro Towers” or whether they should be renamed “petite vegetable towers”, “wheatgrass towers” or “strawberry towers”, these towers are all about performance! They are perfectly complementary to our regular towers.

When buying a new Tower Farm, we usually advise our new customers to consider allocating a certain percentage of High-Density Towers within the total amount of towers ordered in the initial setup of the Tower Farm.

B3. What is the crop yield of a Tower Farm (and recommended crops to grow commercially)?

From a “cash crop” perspective, a Tower Farm operator farming in a climate-controlled greenhouse environment should mainly focus on leafy greens and aromatic/medicinal herbs.

Although over 200 different crops can be grown successfully using our Aeroponic tower technology and fertilizer solution, when it comes to farming vertically indoors, the overhead cost is calculated based on each square meter of operation.

Leafy greens and aromatic herbs do not outgrow the radius of the tower reservoir, which translates in more towers being able to fit within a specific area in comparison to growing tomatoes, cucumbers or any other vine related crops. When growing tomatoes or squash, the plants need to be supported by an outside cage, with average yield of 100g to 175 g per port per 21-28 day growing cycle. Yield for fruiting vegetables like cucumbers and tomatoes depends on the variety. Here are the average crop yields which were experienced by our partners at True Garden and Agrotonomy:

- Tomato cherries: up to 12 to 15 plants per tower maximum = 20 to 40 pounds per plant depending on the variety.

- Tomatoes “regular/ big size” up to 12 to 15 plants per tower maximum = 40 to 50 pounds per plant depending on the variety.

- Cucumbers: 15/20 plants per tower. A cucumber can vary between 100 g (or less) and 250 g. We can harvest about 15-30 cucumbers per plant (many more depending on variety, i.e. lemon cucumbers and other specialty varieties).

- Strawberries: 52 plants per tower. Depending on varieties, we have experienced from 100 g to 2.5 pounds per plant (whether we are growing wild strawberries varieties or large fruit varieties).

- Bell peppers: up to 20 plants recommended per tower maximum = up to 6 -8 pounds per plant depending on the variety.

- Eggplants: up to 15 to 18 plants recommended per tower maximum = 6 to 10 pounds per plant depending on the variety.

- Leafy green and herbs: 52 plants per tower. From 100 to 175 g every 3 weeks. Once again, it all depends on the crop: it takes much longer for basil than it does for arugula… depending on varieties, harvest cycles vary from 14 days to 60 days with harvest cycles every 3 weeks on average.

Once again, the crop yield of a plant will depend on the quality of the seeds, the variety, the growing conditions (light, humidity, temperature, air circulation, elevation, EMFs, etc.).

When considering growing tomatoes, cucumbers, beans or eggplants, there are other agricultural technologies which can compare to our towers in terms of crop yield and quality.

However, when it comes to growing leafy greens and herbs (aromatic and medicinal), we are in a league of our own, where no other agricultural approach can compare to our Aeroponic tower technology: aside from a staggering superior crop yield, our “green crops” feature a scientifically proven increase in nutrition density, antioxidant activity as well as in phenolic values (healthier, tastier, more fragrant and stronger texture), please refer to this study.

Growing leafy greens and herbs that are so superior in terms of nutrient density also means more ‘robust’ plants featuring a stronger natural defense mechanism (no pesticide needed) and a significantly extended shelf life.

B4. How much space needs to be allocated per tower?

Although technically a tower uses less than 1 m², we advise to allow 2 m² (approximately 20 ft.²) per tower: this includes enough space for the towers, the dosing station, the aisle spacing, and the propagation bench area.

B5. What Tower size is right for my Tower Farm?

At Beyond Organic’s Pilot Tower Farm in Kuwait, we use the 13 Pot Regular Towers and the 25 Pot Micro Towers, enabling us to maximize our yield per Square Meter.

Please be aware of the following:

- The 13 pots (52 plants) Regular model is the same height as its counterpart, the 25 pots (196 plants) Micro tower!

- The 11 pots (44 plants) Regular model is the same height as its counterpart, the 21 pots (164 plants) Micro tower!

- The 9 pots (36 plants) Regular model is the same height as its counterpart, the 17 pots (132 plants) Micro tower!

- The 7 pots (28 plants) Regular model is the same height as its counterpart, the 13 pots (100 plants) Micro tower!

- The 5 pots (20 plants) Regular model is the same height as its counterpart, the 9 pots (68 plants) Micro tower!

The recommended size of the towers also depends on the crops being grown. For example, on a 13 pots tower, all 52 planting ports can be used to grow leafy greens or aromatic herbs. However, when growing eggplants, a shorter tower (9 pots/7pots) is better due to the weight of the fruit.

Even indoors, like inside the Orlando convention center in the USA, a Tower Farm can thrive with towers configured with 11 pots (44 plants) with the appropriate artificial lights.

Within a school environment involving young children, we recommend the 5 pots (20 plants) which or the 7 pots (28 plants). Both sizes can accommodate the LED light kit supplied by Beyond Organic.

Of course, if we are talking about a Tower Farm for the cafeteria of a University like the one at UCLA, there is no size limitation.

In the educational market, the size of the towers depends on the age of the children, the facilities, and whether the towers are being used for educational purpose or to produce crops as a commercial Tower Farm (to feed the school).

Prior to selling a fully automated Aeroponic Tower Farm system, we always consult with our customers to define the best tower size strategy for each project.

However, considering that Tower Garden Aeroponic towers are modular in size and can be used indoors or outdoors, it opens a whole world of possibilities.

Have a project in mind? Please submit your consultation request here and we will get back to you as soon as possible.

B6. Can a Tower Farm operate indoor with LED lights?

Tower Farms can be equipped with a state-of-the-art adjustable LED light kit provided by Beyond Organic to operate indoors.

The Tower Farm’s LED light kits are for 11-pot towers (44 plants • 2.5m high) and each kit comes with 3 fixtures per tower.

B7. How long does a set of nutrients last?

Based on our testing at Beyond Organic’s Pilot Tower Farm in Kuwait, each set of dry nutrients lasts up to 2-4 months (based on system size) when mixed at a ratio of 1:300.

B8. What is the labor involved to run a Tower Farm?

Not only our Aeroponic systems allow to save 92% water, 80% space while reducing drastically the risks of pests, a Tower Farm requires 90% less labor in comparison to soil-based farming, for example, in Beyond Organic’s Pilot Tower Farm in Kuwait, with 135 Professional Series towers of 2.9m height each (over 9,000 plants total), only 2 personnel are required; one laborer in charge of farming, and one technician in charge of ensuring all system are always working in tip-top shape.

B9. What is the luminosity requirement of a greenhouse?

Ideal light is natural sunlight, minimum of 12-14 hours per day. The Daily Light Integral required for most food crops for ideal growth is 12-16 moles per square meter per day.

B10. What is the minimum purchase quantity for a Professional Series Tower Farm?

The minimum purchase for a Professional Series Tower Farm from Beyond Organic is generally a 10 Tower System.

Each fully Professional Series Tower Farm system includes the nutrient distribution equipment and containers, the pumps, the irrigation system, the tubing, and connectors. It is indeed a fully inclusive system which is really easy to assemble.

We deliver our Aeroponic Tower Farm systems equipped with a fully automated irrigation system supplying the water and nutrients to each tower on an as-needed basis. Our irrigation system automates the whole process regardless of the number of towers involved.

However, for those looking to create a rooftop tower farm for their homes, please checkout Question C2 in this FAQ below.

B11. Does Beyond Organic offer Tower Farm on-site installation services?

Yes, we always include the on-site installation in our quotations.

B12. Will I get training after I purchase my Tower Farm?

Yes, after each on-site install Beyond Organic conducts, our professional installers will do a quick training to the Tower Farm operators to ensure they can take care of things.

B14. What are the recommended greenhouse key specifications and components for a Tower Farm?

Key specifications and components for Tower Farm greenhouse projects:

• Greenhouse structure's longer side to run north to south ALWAYS

• Tower Farm rows to run north to south ALWAYS

• Full sun exposure and/or supplemental lighting is required for year round production (at least 12 hours of light)

• Oversized Fan and Pad evaporative cooling system

• Cooling pads on north end, and exhaust fans on south

• Thrips screen covering entire north end to minimize insect intrusion

• Seedling propagation always on north end near cooling pad for pest prevention, dedicated seedling grow lights are highly recommended

• Gutter connect greenhouse with min. 4m sidewall height desired (for 2.9m towers)

• 8mm or 10mm polycarbonate on end walls, sidewalls, and top (side walls can be semi-diffused to reduce heat)

• OPTIONAL: Fogging system as stage 2 cooling

• RO water machine recommended

• High end controller – PC based w/alarms, weather station, climate sensors (should be in a dedicated buffer room, usually recommended to be at the entrance in a 4x4 room with an AC unit). Buffer room should also have air-curtain to stop pests from entering

• Concrete floor, White epoxy coating if possible, easier cleaning and better light diffusion

• Roof Curtain System to reduce the intensity of radiation heat in Summer

Below is Beyond Organic's Greenhouse in Al Wafra

B15. Does Beyond Organic provide a suggested Tower Farm layout/blueprint?

Yes, we can work closely with our clientele to customize solutions according to each Tower Farm project.

C: Other Common Questions

C1. Can I purchase just 1 or 2 towers for testing purpose?

Unfortunately, Commercial Grade Tower Farms cannot be tested through the use of small quantities. Anything smaller than a 10 Tower System will not be a good value for money for the end-user when taking the irrigation system and the mineral solution costs into consideration, hence why testing samples simply cannot be offered.

If you are interested in visiting our Tower Farm, please contact us. You can also check the pictures here.

Furthermore, our Tower Farm systems are not “a novelty.” The technology has been implemented for over 10 years in USA & Spain, and numerous Tower Farm references operating successfully in all climates including one similar to the one in the Kuwait (i.e., our partner Tower Farm True Garden in Arizona, as well as UAE & KSA) exist. The technology is far beyond the testing phase of development.

In the world of Aeroponic vertical farming, the Tower Farms offered by Beyond Organic are made by the actual originators and pioneers of such technology over a decade ago from the USA. We do not sell one of these “Chinese-plastic-fantastic-cheap-tower” without references nor track record!

Our Tower Farm systems are being used by over 100,000+ end-users and hundreds of profitable commercial Tower Farms worldwide are still in operation.

However, we know testing is an important part of anyone’s research, and thus, for those interested in testing the waters before diving into the technology, you can always purchase Towers from our Residential Series. All details can be found here. However, bear in mind that while it will be a fun experience, the Residential Series will not lead to conclusive results to benchmarking the potential of our technology on the commercial level, the only way to achieve that is through a proper Commercial Grade system.

C2. Can I implement a System on my rooftop?

Definity, for clients looking to implement a rooftop system, we recommend a 6 Tower system, where each tower is 2.1m high (36 plants), generating a total of 216 plants at once!

Please contact us and we will be delighted to work something out!

C3. What is the average price of greenhouse?

An average fully automated and climate-controlled greenhouse generally runs between 40 to 70 KWD/Sqm.

The price also varies based on the quality of the greenhouse amenities (atomizers, fans, cooling pads, electrical setup, off-the-grid equipment, insect screens etc.).

C4. Does Beyond Organic provide greenhouse services?

This service consists of consulting with the client in regards to their greenhouse needs. And based on the nature of the inquiry, we might also consult our partners in USA & Spain.

Have a project in mind? Please submit your consultation request here and we will get back to you as soon as possible!

C5. Are schools/charities/nonprofit organizations/associations eligible for discounts?

Each project is treated on a project-by-project basis, so each will have its own pricing formula based on the size of the project.

However, we greatly value our communities and educational resources, contact us and we will be more than happy to work a great deal!